SCL 101-1K

Our

smallest equipment for green hydrogen production. It produces 1 kg of hydrogen

per day and is primarily intended as a demonstration system.

Delivers

more than 99% pure hydrogen and uses a fixed oxygen absorption filter.

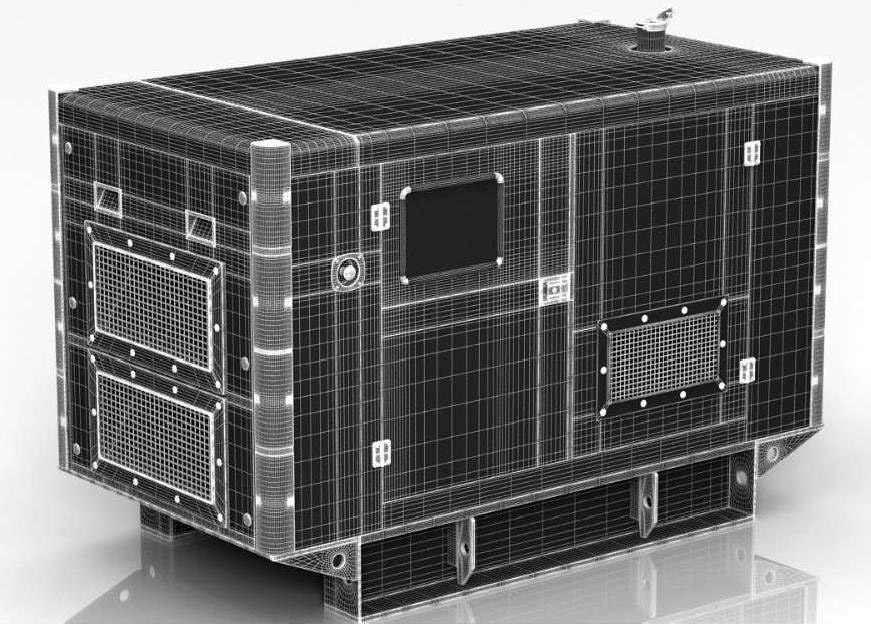

SCL 301-10K

Mobile

system that produces 10–20 kg of hydrogen per day.

Delivers

more than 99% pure hydrogen using a graphene filter.

SCL 701-200K

20-foot

container capable of producing 225 kg of hydrogen per day (100 Nm³/h).

Five

containers can be combined to produce 1000 kg/day, with four generating

hydrogen and the fifth handling hydrogen purification using cryogenic

techniques to achieve 99.99% purity.

Can be

placed outdoors in ambient temperatures ranging from -30°C to +50°C. For more

extreme temperatures, adaptations can be made.