Facts about hydrogen

Hydrogen

is our most common element, making up 75% of all mass in the

universe. It is our smallest and lightest element. At atmospheric pressure and 20°C, 1 kg of

hydrogen occupies as much as 11.9 cubic meters.

This creates

problems for transportation and storage. The gas therefore needs to be

compressed or cooled to become more concentrated. Compression requires very

high pressure to transport or store hydrogen effectively. At the same time,

hydrogen causes embrittlement of metals and leaks through the tiniest cracks.

If the gas

is instead frozen into liquid form, a temperature of -253°C is required—just

above absolute zero. All of this results in increased energy costs.

Pipelines

can be an efficient way to transport hydrogen over long distances, but it is

also wise to place hydrogen production as close to the point of use as possible

One way to

reduce losses in transport and storage is to convert the hydrogen into ammonia,

ethylene, methanol, ethanol, or other substances that can be used in the green

transition. SCL Energy holds several patents and technologies for this and

collaborates with multiple researchers in the field.

Production and usage

Industry uses enormous amounts of hydrogen, but

only 2% is produced through water electrolysis and renewable electricity. 76% comes from natural gas and 22% from coal gasification.

Hydrogen from

natural gas is produced through steam reforming, where the gas is heated to

between 700–1100°C together with a metal catalyst. Hydrogen and carbon dioxide

are formed when steam reacts with the methane in natural gas.

Similarly, hydrogen can be produced from coal,

which results in the highest emissions.

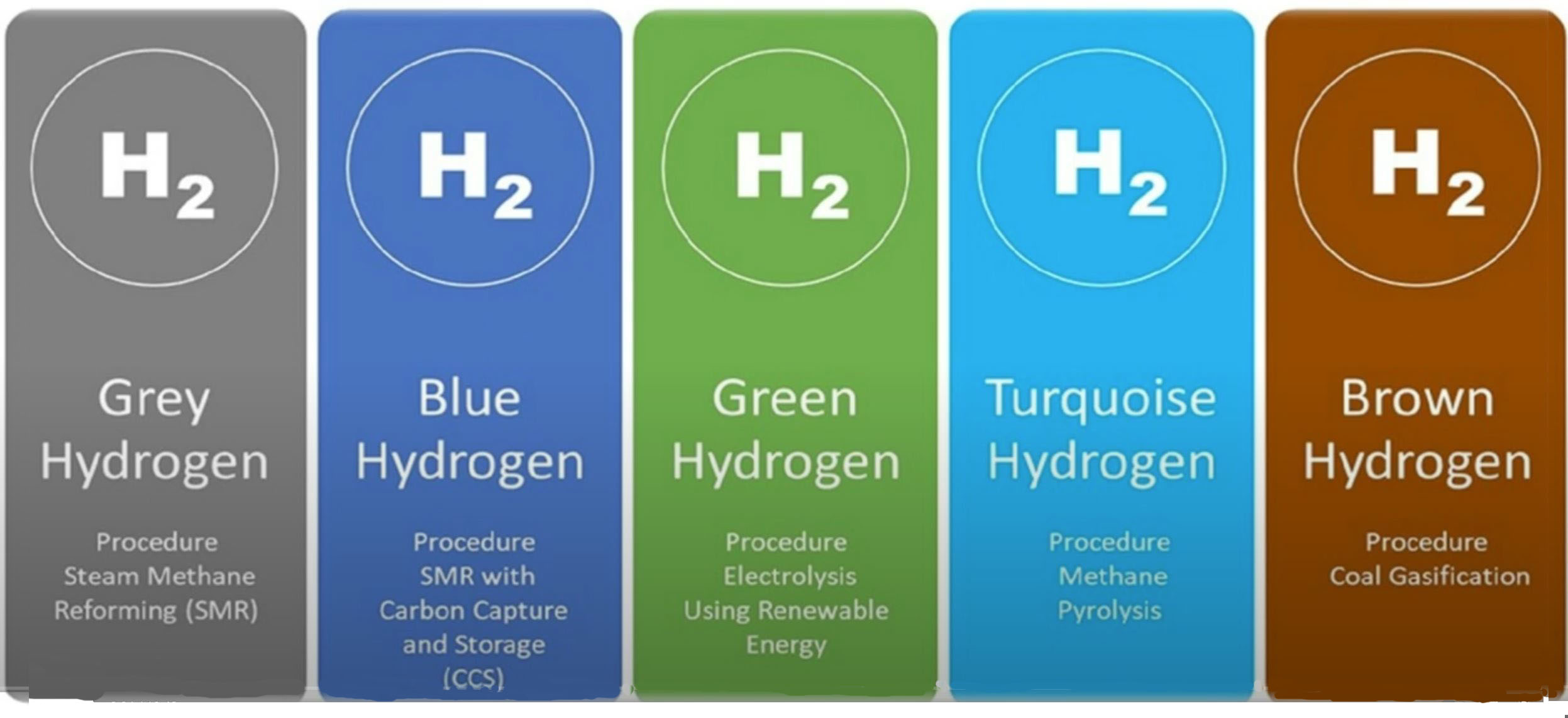

Even though hydrogen is invisible and odorless, it has been assigned different colors depending on how it is produced. Here are the most common:

Gray hydrogen is produced through steam reforming of methane and results in high carbon dioxide emissions.

Blue hydrogen is produced the same way as grey but captures the carbon dioxide. However the technology for this faces challenges.

Brown hydrogen is made by gasification of brown coal. If black coal is used it's called Black hydrogen. It is clearly the dirtiest method.

Turquoise hydrogen is made through pyrolysis (oxygen-free high heating), which yields hydrogen and solid carbon instead of carbon dioxide. This method is still in development with limited use.

Green hydrogen is produced via electrolysis and renewable energy. It is the great hope for the future and the environment.

Many stopped Hydrogen Projects

Sweden has many large planned hydrogen projects, but only a few have been realized. Among the reasons presented, the most important have been economy and electricity supply. It has sometimes been difficult to generate as much green energy as required, and investment plans have been hard to finance.

It can be

difficult to make the investment profitable when the price of gray hydrogen is

so much cheaper than green.

According

to a 2025 report from Bloomberg NEF, the cost to produce 1 kg of green hydrogen

is $3.74 – $11.70, while it is only $1.11 – $2.35 for 1 kg of gray

hydrogen.

With technology from SCL Energy, only one-fifth of the green electric energy is needed, and the production of green hydrogen becomes significantly cheaper. Then many previously canceled planned investments could be carried out and become economically successful. Read more about the technology under the menu "Elektrolyzers".