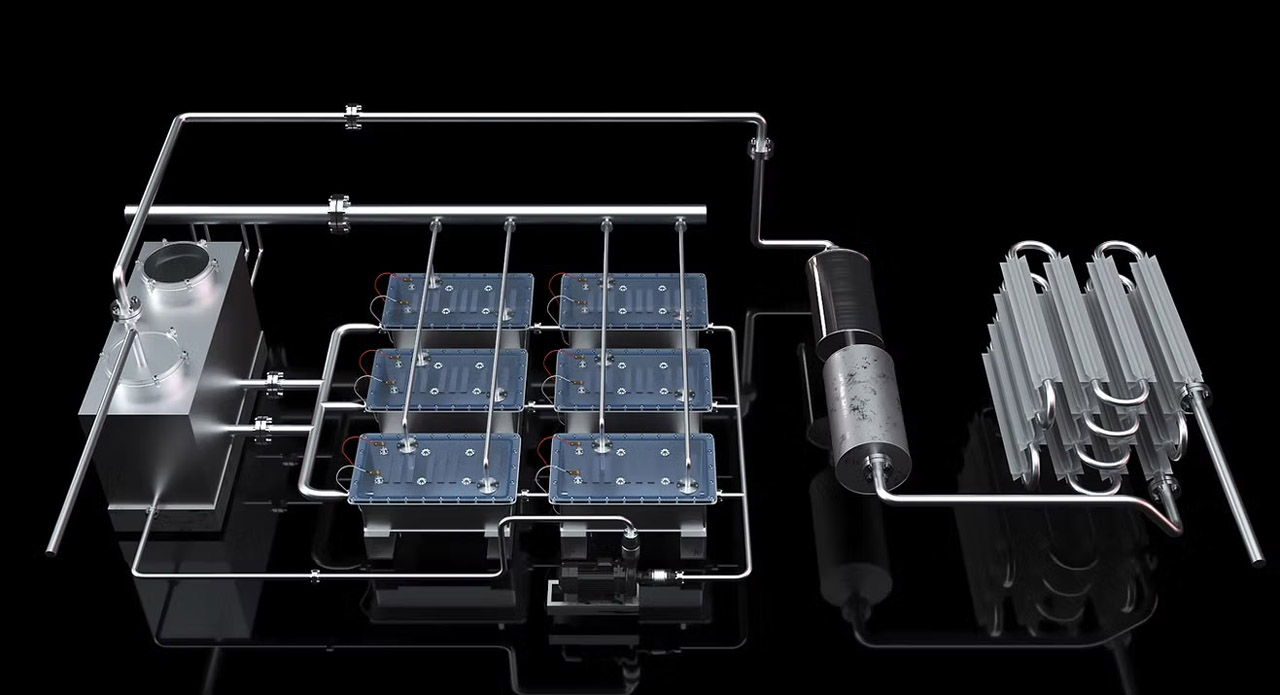

Advantages of SCL's E-beam Electrolysis

The

biggest and most remarkable advantage of SCL's technology is the low amount of

energy required for hydrogen production. The electrical energy needed is only

one-fifth compared to other electrolysis methods. It’s so astonishing that you

have to see it to believe it.

Another

advantage is that any type of water can be used. Since 10 liters of water are

needed for every kilogram of hydrogen, water consumption is high, and if the

water needs to be purified, it adds extra steps and costs.

An

additional benefit is that the process has no energy losses. Energy losses

typically produce heat that needs to be cooled. In this case, the water stays

around 40°C the entire time, and no cooling is required.

The World’s Cheapest Green Hydrogen

Several

companies are investing heavily in research to produce hydrogen with lower

energy losses. The large hydrogen projects being planned require vast amounts of electricity. This makes the projects expensive, and it may be difficult to supply all the electricity needed.

That the

technology from SCL and Professor Lee can produce 1 kg of hydrogen using only

10 kWh/kg sounds too good to be true. This opens

up completely new possibilities for achieving profitability and reduces

dependence on available green electricity.